Implementing a powerful ERP system like Odoo can empower your manufacture actions in different ways, like:

- Improving operational efficiency

- Boosting productivity

- Streamlining processes

To leverage the manufacturing steps in your business, it’s necessary to understand some fundamental aspects before diving into the implementation process. This article will guide you through the top five essentials to know before implementing your manufacturing flow in Odoo.

This will help you to prepare appropriately and ensure a smooth transition as you integrate the system with your existing processes. From understanding the system capabilities and the possibilities for customization, to anticipating the most common challenges that companies face implementing Odoo manufacturing, this guide covers it all.

1. Bill of Materials (BOM) Management

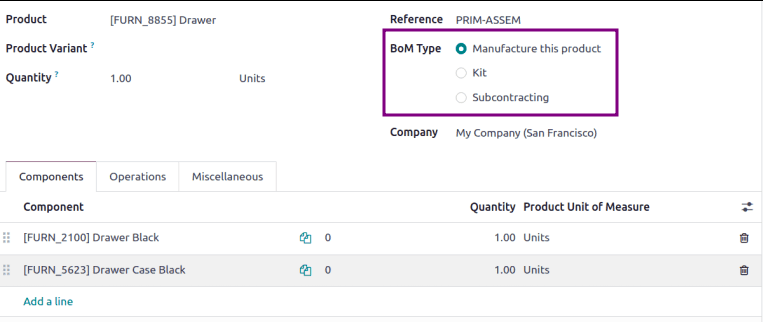

Creating BOM’s

The bill of materials management is one of the most important aspects of manufacturing. Before implementing, it’s important to have a clear understanding of your product's structures, including all raw materials, components and subassemblies. Odoo has three types of BoMs that will allow you to assemble your product, which are:

- Manufacture- Using components mentioned in the BoM to manufacture a final product.

- Kit - Any products that are packed together or sell products together as a single product.

- Subcontracting - Products that are manufactured by a subcontractor, not by your company.

- BOM Components

The components you enter should have specified details such as quantity, unit of measurements, and any other relevant attributes. If during the manufacturing process any byproducts are being produced, they should also be defined.

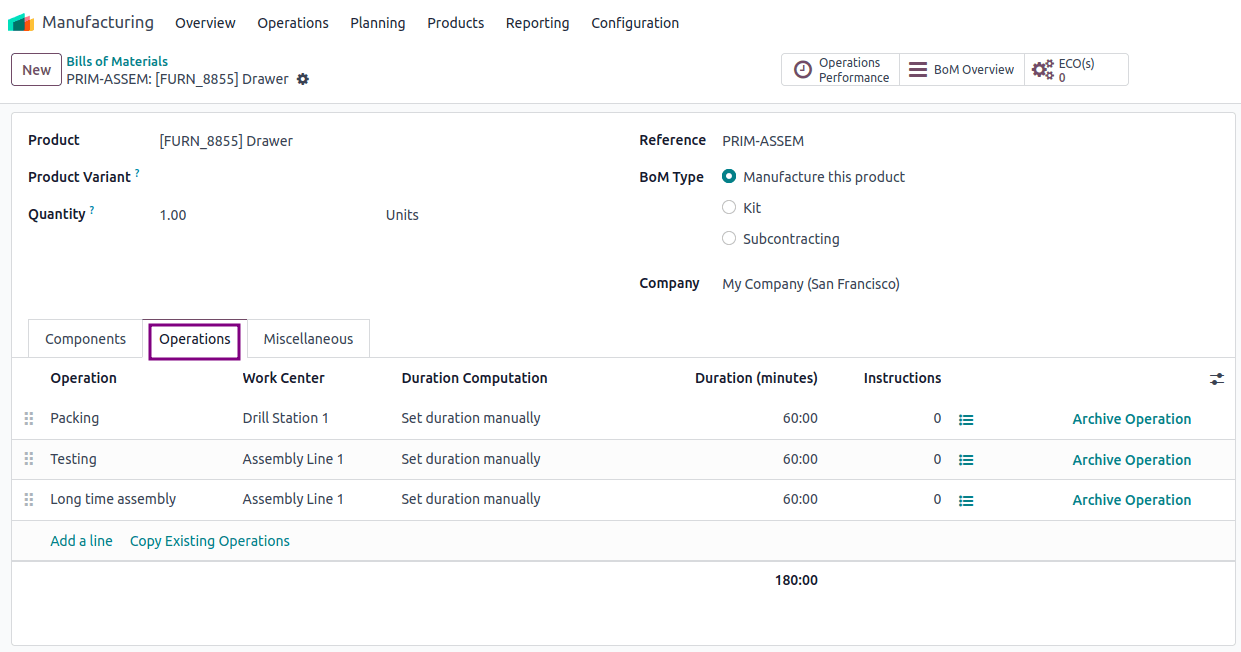

- Operations flow

Beyond the components you’ve entered, it’s necessary to have your workflow well defined. This definition is set in the “Operations'' tab, where the operations and their respective work centers are described. This will be explained below with more detail.

- BOM’s Hierarchies

For the final product, there is a BoM with different components, and these may or may not have their own BoM for which a hierarchy will be created. Odoo will respect this hierarchy based on your input.

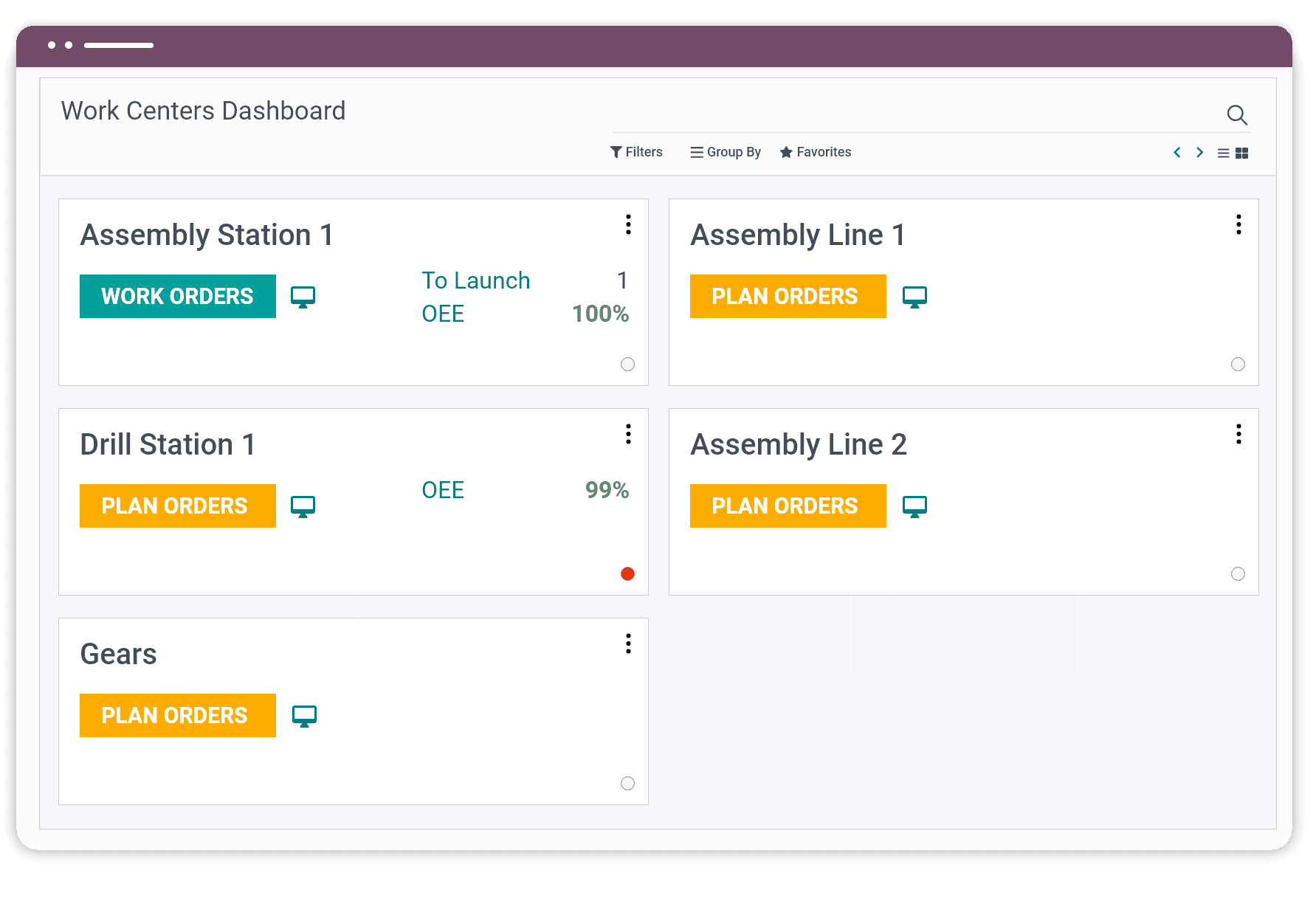

2 - Work Centers

- Work Centers Definition

For efficient production, the work centers must have the following defined:

- the name,

- working hours,

- the production information (such as time efficiency or duration of a work order),

- capacity (the number of units that can be produced in parallel),

- the OEE Target (Overall Effective Efficiency Target),

- the costing information with the cost per hour by workcenter and per employee,

- the operations where it is important to identify the preparation time (time before production starts),

- the cycle time of the operation and the cleaning time.

If you would like to know more about manufacturing costs, check out these helpful articles:

3 - Quality Control and Inspection

- Define Inspection Points

To ensure that the quality check control is done properly, it’s essential to have adequately defined what the key stages in your production processes are. This helps you to determine where the quality checks should be implemented. It goes without saying that the inspection criteria is an important factor to establish, since specifying the aspects that need to be checked will ultimately affect the quality of the end product.

- Set Up Quality Checks

For each control point, it’s important to define what types of checks will be performed. Types of checks include measurements, functional tests, and other relevant checks depending on the product in question.

4 - Inventory and Warehouse Management

- Inventory Locations

Identify and create the different inventory locations in your warehouse like storage zones, quality control areas, shipping docks or others. Base these inputs on your particular business needs and the types of products you’re manufacturing. After this it’s essential to have a hierarchy and structure for these locations, which will provide better organization of your warehouse.

- Stock rules

With the aim of always keeping your stock under control, Odoo offers different functionalities like: Reordering Rules: essential for defining the minimum and maximum stock levels for each product to trigger automatic replenishment; Lead Times: determining lead times for procurement and production is crucial to avoid stockosuts and ensure timely replenishment; Safety Stock: to prevent unexpected demand spikes or supply delays.

- Barcode Scanning

To improve the efficiency of your inventory and warehouse, the barcode is a good way to track your receiving, inventory counts, picking, and shipping. This makes it possible to reduce any manual entry errors.

If you would like to know more about how you can implement Odoo barcode in your company, check out this more comprehensive article:

The Significance of GS1 Barcode and its Integration in Odoo

5 - Production Planning and Scheduling

- Demand Forecasting and Resource Availability

The Odoo manufacturing module analyzes demand forecasts based on historical data, customer orders and market trends. This is essential information for planning and scheduling timely fulfillment of your orders. The evaluation of resource availability is also crucial for Odoo to efficiently plan production.

- Production Order Management

Your production orders can be planned within Odoo, defining the bill of materials and work centers required for each order. The system automatically schedules production orders based on priority, resource availability, and lead times, thereby optimizing overall production flow.

- Real-Time Tracking and Progress Monitoring

Odoo allows you to track production progress in real time, monitoring resource utilization. The dashboard and reporting tools are excellent ways of optimizing your production workflows by identifying bottlenecks in your production line. This allows you to better allocate your resources, ensuring optimum use of machines, labor and materials.

Conclusion

Successfully implementing Odoo Manufacturing requires understanding the integration of bill of materials management, work centers setup, quality control & inspection, inventory & warehouse management, and production planning & scheduling. By focusing on these five important factors, you’ll be able to implement Odoo Manufacturing seamlessly, which will ultimately improve efficiency and set the stage for sustainable business growth.

If you have any questions about how to successfully implement Odoo Manufacturing, feel free to Contact Us

Follow Us on Social Media

Stay connected with ERPGAP and follow us on this journey. You can view updates on LinkedIn and Twitter.